Most Efficient and Highly Effective Fume Extraction System Manufacturer, Supplier & Exporter in India

Manufacturing efficient Fume Extraction Units and industrial air purification solutions, including fume exhaust systems, dust separation units, and application-specific air filtration equipment at best price in Ahmedabad, Gujarat

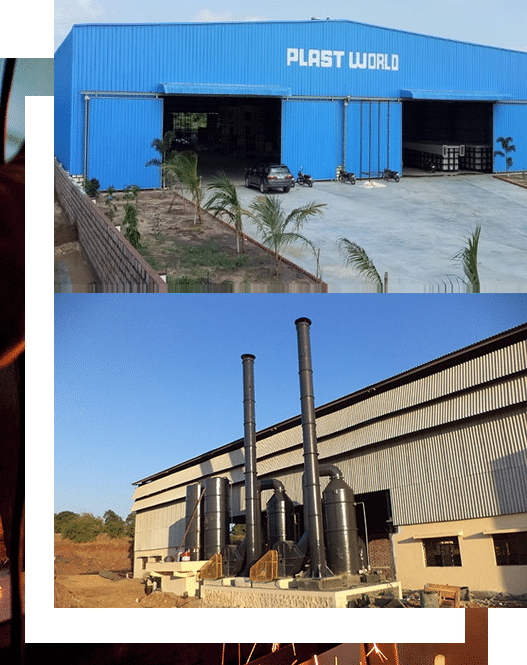

Plast World is a well-known manufacturer and supplier of Fume Extraction Systems, which are used to remove dangerous fumes, smoke, and other air pollutants produced during industrial processes. The fume extraction system is essential in ensuring the safety and health of the workers, as well as preserving the air quality levels within the work environment.

The Plast World Fume Extraction System is an ideal blend of technology, dependability, and functionality – it offers effective solutions to industries that require a clean and safe working environment in different parts of the world. We being a top Fume Extraction System Manufacturer, use advanced technology and accurate engineering in all our production processes. Our systems are evolved to suit the high standards of the present manufacturing industries, especially in the plastics industry, where safety, efficiency, and environmental responsibility are of paramount concern.

Reliable Fume Extraction Systems Supplier & Exporter

At Plast World, we strive to achieve excellence that starts at the design level. We use the latest engineering principles to design the longest-lasting and durable fume extraction systems that can satisfy the top standards of performance.

There are many plastic manufacturing methods where our systems have been successful in eliminating harmful gases, fumes, and particles at the point of origin, including thermoforming, extrusion, and injection molding. This is a proactive measure that indicates our interest in sustainability, the safety of workers, and environmental concern, and we ensure that we meet stringent pollution control practices.

Our Acid & Zinc fume extraction systems in India are fitted with high-efficiency filters that capture pollutants and do not release them into the atmosphere. The advanced filter media and optimized design of airflow increase the life of filters, minimize maintenance, and decrease the operation cost.

Both systems also have intelligent control technology, which makes monitoring and regulation of airflow easy to ensure that production remains the same under different production conditions.

Plast World is a reliable Fume Extraction System Supplier that provides technology-focused solutions to enhance workplace safety, environmental objectives, and productivity of the overall operations.

Our Products

Our Professional Services

We are a team of professional and skilled experts in all domestic spheres. We offer a wide range of serve you with any unconventional household needs:

01

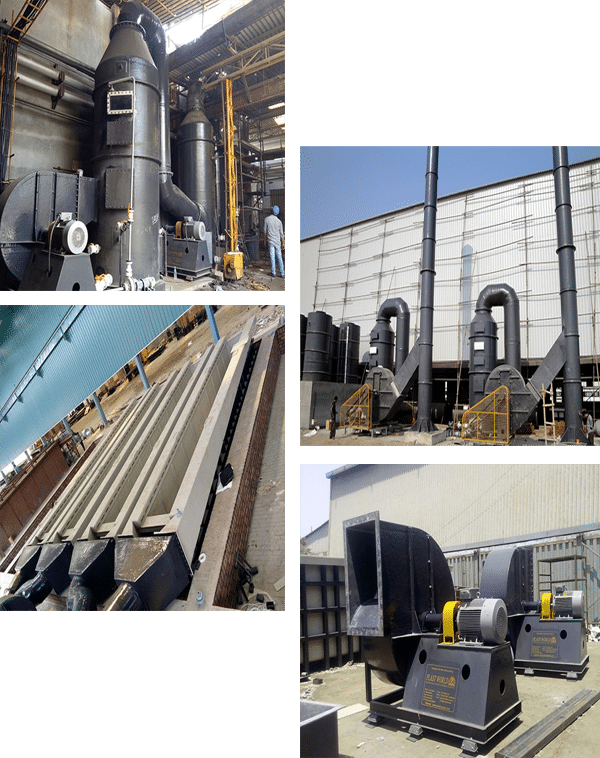

Wet Scrubbers

Our wet scrubbers are very efficient in cleaning up polluting gases since they are washed using an appropriate liquid solution that neutralizes fumes and emits clean air into the atmosphere. These systems are well constructed to suit the nature of gases that are generated in your process to ensure maximum purification and safety.

02

Hoods, Ducts & Valves

Our hoods, ducts, and valves are designed and supplied using materials that are durable, like FRP, PVC, and PP, to contain corrosive gases. The overall design of these parts is important in the overall performance of the fume extraction system. All the parts are designed to have a smooth airflow and durability.

03

Fans or Cooler

We have fans and blowers that support the required suction to bring up infected air and fumes in the work area. They are constructed with tough and resistant materials against corrosion, such as mild steel, FRP, or stainless steel. These units have a high level of airflow, which is essential in the removal of fumes and the safety of work.

Key Features of Fume Extraction System

High-Efficiency Fume Capture

The capture hoods and ducts are carefully installed in the areas where the fumes originate in order to capture them at the originating point, thus containing the maximum amount of toxic vapors and dust as well as chemicals.

Corrosion-Resistant Materials

These systems are constructed using materials like FRP, PP, SS316, or PVC that are very durable, hence suitable for corrosive and very acidic industrial environments.

Multi-stage Filtration System

These systems are fitted with pre-filters, HEPA, carbon filters, or wet scrubbers, which filter as much as 99.99 percent of the particulates, chemical vapors, and odors.

Adjustable Airflow Ability

Airflow is available in 500 to 50,000 and above CFM, a durable type of industry, quantity of fumes, and workspace area.

Energy-Efficient Blowers

Centrifugal blowers with high-performance, low-noise will guarantee high suction and less power consumption as well as stable negative pressure.

Smart Control and Management

PLC/SCADA-based optional automation is offered to monitor the level of gases, temperature, airflow, and system faults in real-time to operate more safely and smartly.

Adherence to Safety Criterion

The systems are all created in compliance with the OSHA, CPCB, and ISO standards, thus being reliable in use in chemical, metal finishing, pharmaceutical, welding, and laboratory applications.

Our Fume Extraction System Specifications

| Feature | Specifications & Options |

| Materials Used | Stainless Steel (SS), FRP (Fiberglass Reinforced Plastic), Polypropylene (PP) |

| Filtration Stages | Pre-Filter → HEPA Filter → Activated Carbon Filter Wet/Dry Scrubbers (can be configured according to requirement) |

| Airflow Capacities | 500 CFM (small lab) to 50,000 and beyond CFM (large industrial facility) |

| Types of fans and blowers | High-efficiency centrifugal fan, energy-efficient motors, and acoustic enclosures of low noise. |

| Energy Efficiency | Optimized airflow design with minimum power consumption and maximum performance. |

| Noise Levels | Designed for < 75 dB with soundproofing options |

| Control Systems | PLC automation, SCADA automation, and a friendly control panel. |

| Customization | Modular designs, flex ducting, industrial-specific welding, chemical, galvanizing, and lab applications. |

Fume Extraction System Applications

Steel and Metal Processing Plants

Applied to curb the fumes, smoke, and dust being discharged by furnaces, melting, and casting operations.

Welding & Fabrication Units

Eliminates welding fumes, metallic particles, and smoke at the point to enhance workplace safety.

Chemical & Pharmaceutical Industries

Practically removes acid vapours, solvent fumes, and dangerous gases during chemical operations.

Waste Treatment and Incineration Plants

Regulates unhealthy, chemical, and medical waste burning by controlling toxic combustion gases and odors.

Industrial Boilers and Power Plants

Handles flue gases, hot fumes, and particles in a more efficient and safer manner.

Laboratories & R&D Facilities

Precautions safe handling of chemical vapors and gases in test and research.

Electronics and Soldering Operations

Traps fumes released in soldering, brazing, and electronic assembly process.

General Manufacturing Industries

Enhances the quality of air in areas that use heat, combustion, or chemical reactions.

Design of Fume Exhaust System

We at “Plast World” design proficiency professionals cover the system by using the latest techniques in Framework of Fume Extraction. As we are having full CAD design facilities provide specific application expertise by centering upon clients necessities providing the most appropriate and cost effective solutions. The Impact of Fume Extraction on life is it human or animals affect the skin from outside, affects the lungs when we breathe in. Further not only the human life is affected but also trees and leaves vegetation to get affected by losing color and life. As there are various equipment which is used for the designing the Fume Extraction system.

What is Fume Extraction System?

A Fume Extraction System is a high-tech system of industrial ventilation, which can eliminate fumes, dust, vapors, and poisonous gases in the manufacturing facility. It is crucial to the preservation of the quality of air, the safety of workers against exposure to dangerous substances, and adherence to environmental standards.

In these systems, contaminants are trapped at their source by the use of hoods, ducts, filters, and blowers. A strong fan forces the contaminated air into a filtration system, which separates the dangerous chemicals and particulates, then emits clean air into the working chamber. A series of filters can be applied to obtain high levels of purification depending on the application.

Modern fume extractors are small, use less power, can be easily serviced, and their designs are frequently ductless, meaning that they do not need any elaborate ventilation system to recycle clean air.

These systems are commonly used in industrial processes, including welding, plastics, and chemical handling, to get rid of harmful air pollutants, decrease respiratory hazards, and create a safer, healthier workplace.

For Installation each small scale unit’s owner desires know the system basic properties

- It should be economically affordable

- Required more space

- Easy to maintain

- Consume low power

Fume Extraction System

Industries We Serve

Powder Industry Manufacturer in india

Metal idustry

Steel idustry

Food and Agricultural Industry

Frequently Asked Questions About Fume Extraction System - FES

1. What is Fume Extraction System?

A fume extraction system is a device that uses a fan to draw fumes and dust particles into a confined filtration system utilizing negative airflow.

2. What is Use Of Fume Extraction System?

Fume extraction systems are used to reduce hazardous compounds in the air below the permissible exposure limits (PELs) specified by Plast word.

3. What distinguishes Plast World brand from competitive brands?

In today’s environmentally aware society, there are numerous dissimilar alternatives available to those wishing to purchase an air cleaning system. It is sometimes difficult to sort through the various claims made by manufacturers. Often prices are radically different for products that, on the surface seem similar. However, there are numerous main advantages the Plast World brand offer:

- Heavy-duty construction

- Long-life blower motors

- User-friendly design makes maintenance and filter changing fast and simple. Most competitive brands require tools just to change filters.

- Accurate specifications. We do not make false CFM and Filter claims. Many competitors inflate the numbers.